Dry Room System

Post-Management through abundant Design and Construction Experience

Design and Construction for Energy-Saving Ultra-Dehumidifying Dry Room,

Grafting High-reliable dehumidification HVAC&R equipment

Recently, due to the high technology of the industry, the air condition of the production line is changed to close to the extreme conditions of air conditioning, and the demand for the HVAC equipment that meets such conditions is increasing. In addition, it is necessary to dehumidify the entire manufacturing room as the processed material may interfere in product when it reacts with the moisture.

The room where these dehumidification conditions should be maintained is called a Dry Room, and indoor air condition less than DP -10℃ is especially called Dry Room Condition. For this reason, it is distinguished from the conventional low humidity room (relative humidity RH 10~30%).

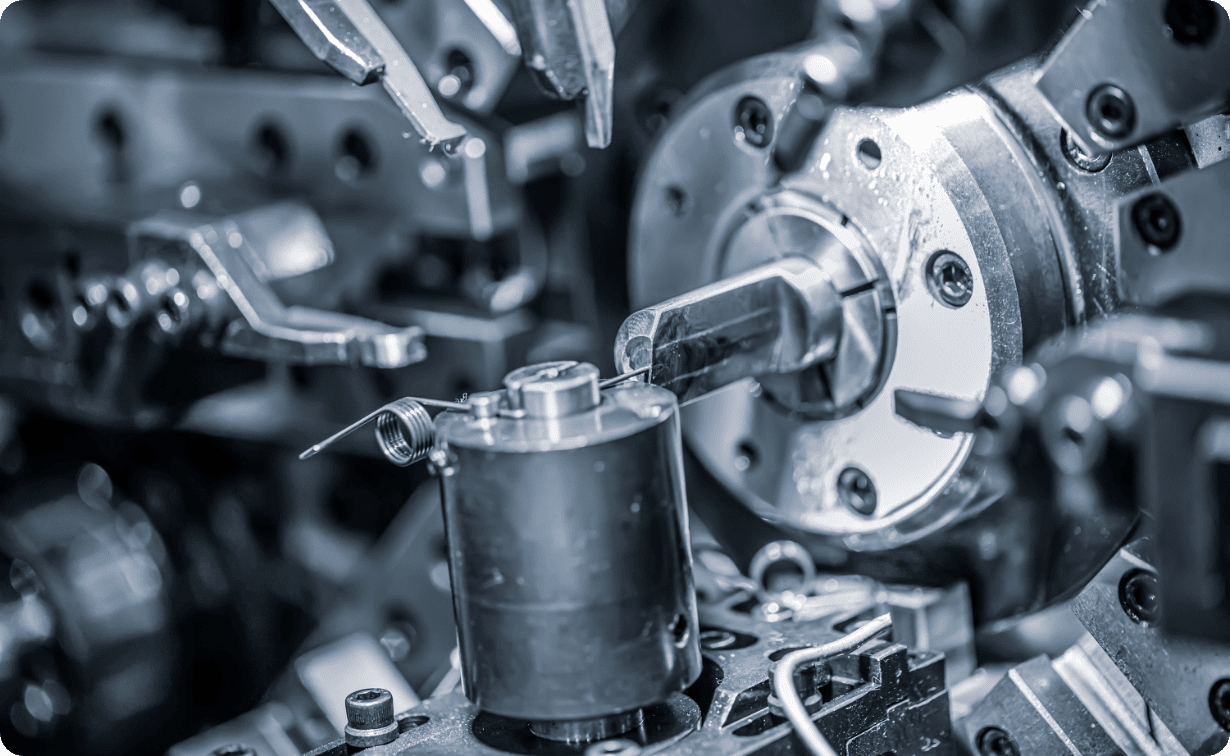

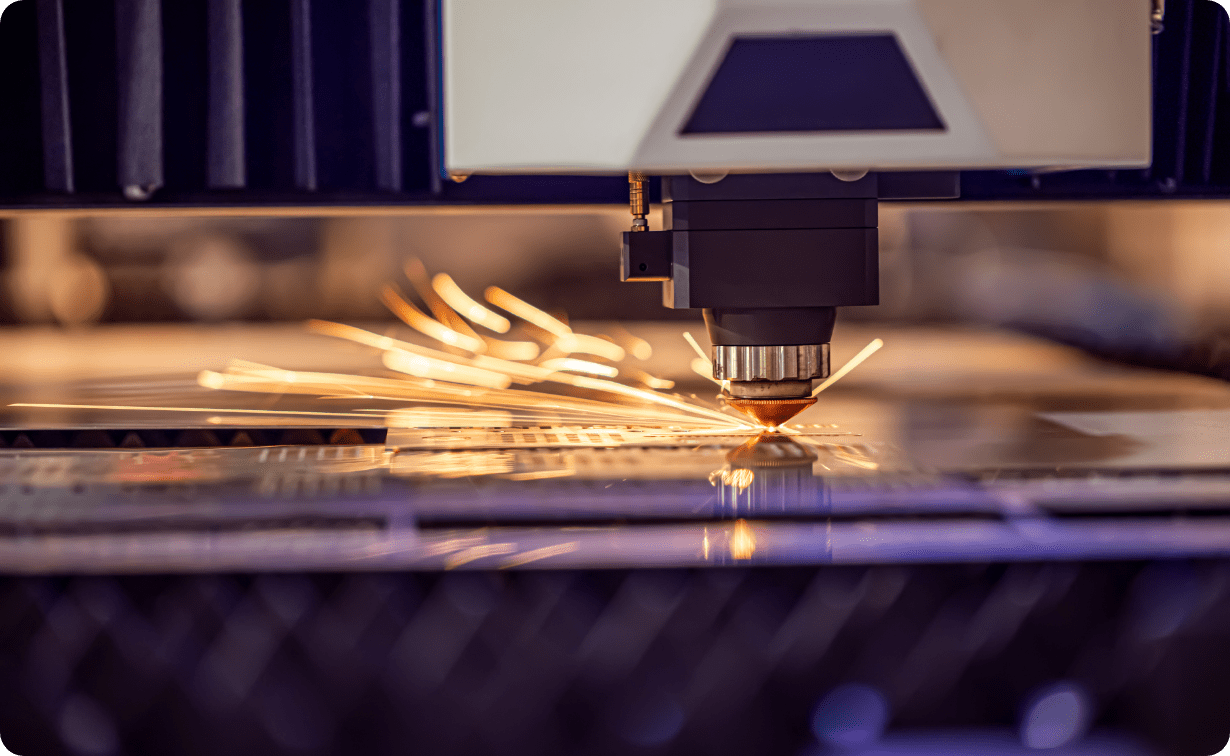

Main usage of the dry room includes lithium battery manufacturing line, pharmaceutical manufacturing line, semiconductor manufacturing line and product storage warehouse etc.

The initial investment and operating costs of HVAC equipment that generate low humidity air are significantly higher than the general air conditioning equipment. In order to reduce the initial investment and operation cost efficiently, it is necessary to improve the performance of the equipment, optimize the system design and rationalize the construction. In order to make super hybrid dehumidification system to be more efficient and economical in design and construction, CK Solution is continuously pursuing improvement of R&D on the equipment and entire system.

Applications