High-Reliability HVAC in Indoor Environment

Grafting Energy-Saving Equipment and Post-Management

through Wide Experience of Design and Construction

Clean Room is a space in which cleanliness is systematized by measuring the number of dust particles according to the size of the indoor dust particles and organized and standardized by class.

In many industrial fields, to control the environmental conditions of the manufacturing process below a certain range is a critical factor in high-quality production technology.

Indoor environmental condition of the manufacturing process needs to be considered with various key factors such as temperature, humidity, consistency of airborne dust, airflow speed, light intensity, noise, vibration, and storage.

Under these environmental conditions, a room that controls the airborne dust concentration below a certain level is called a Clean Room.

We provide a total solution of clean room technology that covers not only industrial clean rooms that require such clean conditions, but also bio clean room that removes biological pollutants from design and equipment manufacturing, as well as precision construction and post-management.

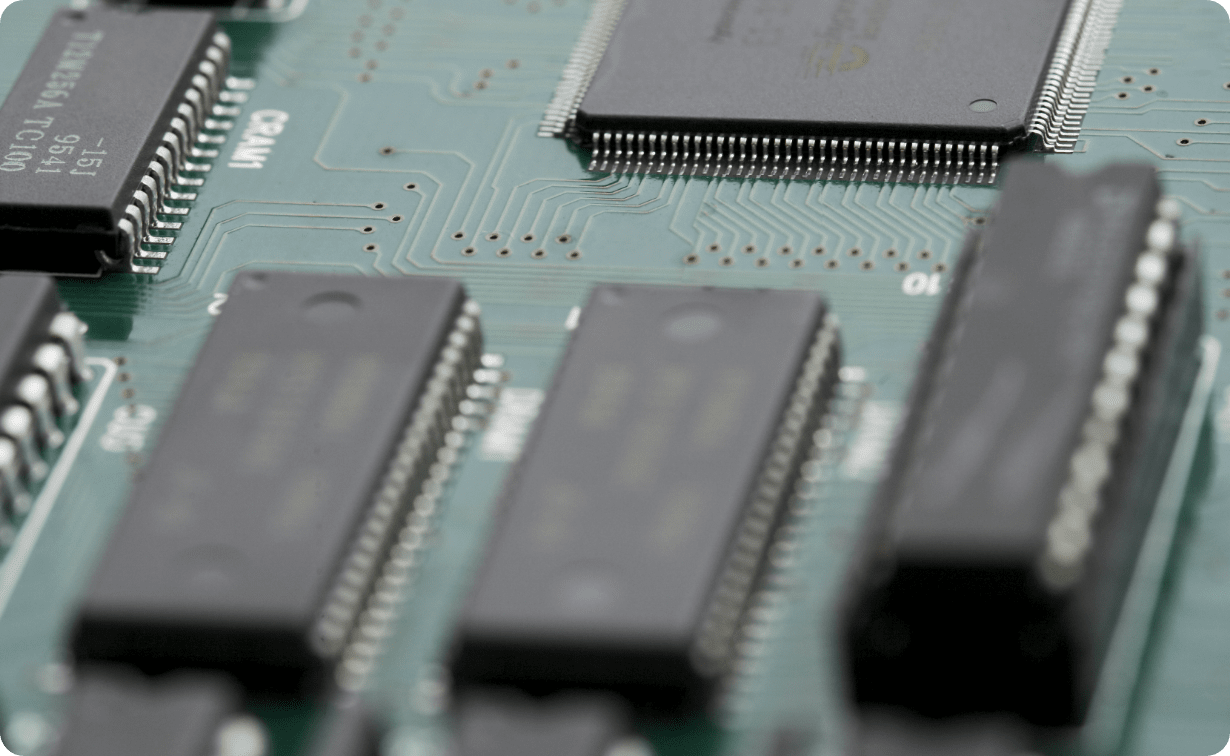

Industrial Clean Room

The precision, micronation, high-quality and high-reliability products are urgently needed due to the rapid development of industries such as semiconductor manufacturing, aerospace, electronics, and precision industry.

Once the suspended particles in the room stick to the products that manufactures in the electronics industry, film factories, and precision machinery factories, they cause the product defects and greatly affects the reliability and the production rate.

Therefore, the entire plant or the space where important work is performed should be kept clean so that the indoor environmental conditions required by the production process can be satisfied. This indoor space made of required cleanliness is called ICR.