Conditioning System Low-Temperature

Storage System Environmental

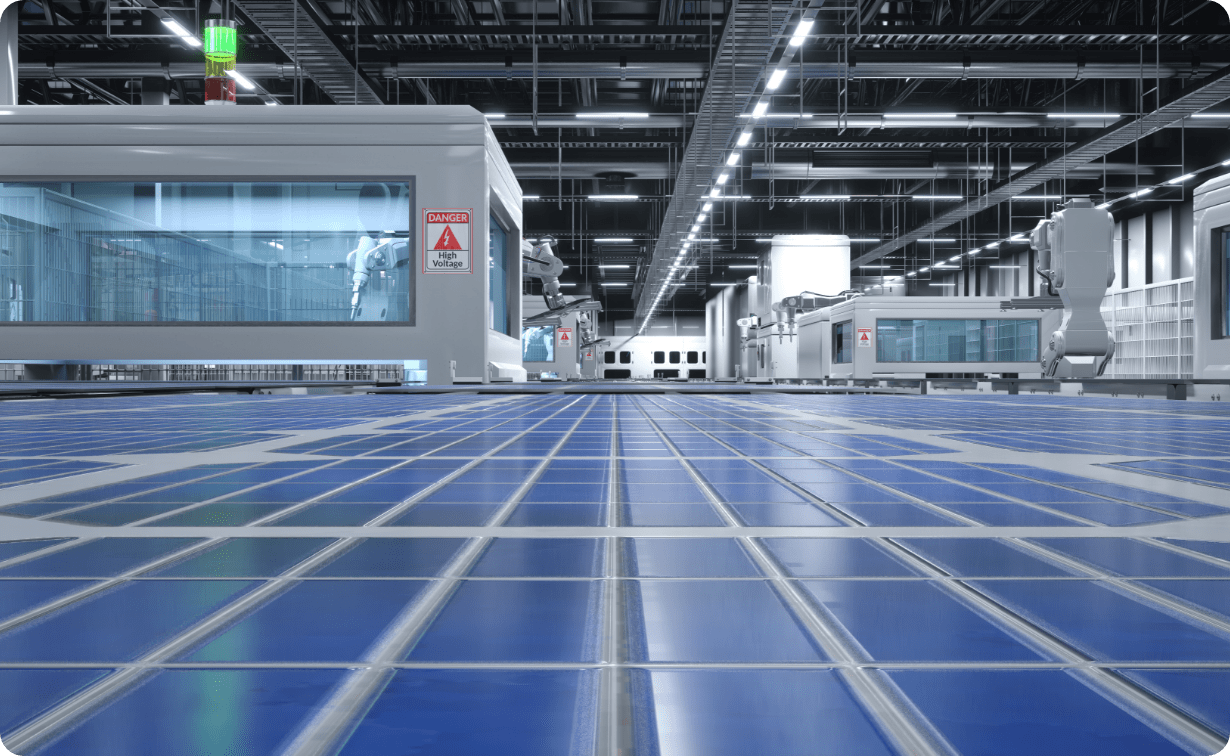

Plan System Mechanical Facilities Special Utility

Construction Utility Facilities

Construction

Environmental Plan System

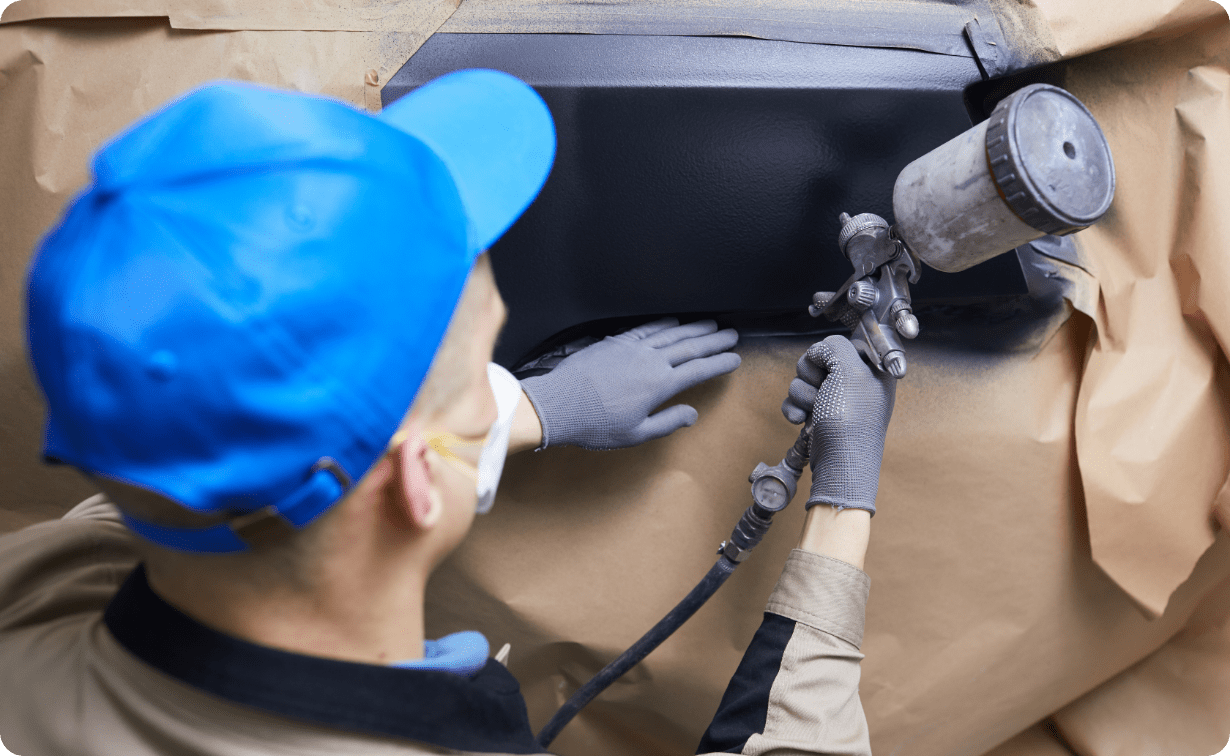

Efficient Prevention of Air Pollution

Optimal Incineration of VOC, Regeneration Technology, Improvement of Air Environment

Volatile Organic Compounds (VOC) is mostly generated by human industrial activities, and because of the rapid increase of using automobiles or the use of various fossil fuels, this problem is being severe in metropolitan areas where many people are densely living.

In recent years, VOCs released into the atmosphere represent as an environmental problem in landfills that handles increased waste due to the production and consumption growth.

Compounds belonging to volatile organic compounds (VOC) include general hydrocarbons such as aromatic and aliphatic hydrocarbons (Paraffin and Olefin), and heterogeneous hydrocarbons containing nitrogen, oxygen and halogen elements (aldehydes, ketones, etc.).

In particularly, VOCs such as aromatic and halogen hydrocarbons, may directly harm to the environment and health as a compound itself, or such as aliphatic hydrocarbons participate in photochemical reactions in the atmosphere cause a secondary harm such as photochemical oxides. Olefin hydrocarbon compounds with double bonds between carbon and carbon atoms are already well known for their high photochemical reactivity.

Among VOCs, most aromatic hydrocarbons such as benzene, can cause a strong carcinogenicity and leukemia, central nervous system disorders, and chromosomal abnormalities. Chlorinated hydrocarbons which produce photochemical oxides by reaction of the destruction of the Ozone layer, global warming, and the chain reaction of volatile organic compounds occur photochemical smog, which cause the eye irritation, reduce visibility, and damage to animals and plants and crops.

Ozone promotes the formation of sulfuric acid dust which causes the acid rain by oxidizing SO₂ in the atmosphere and makes an irritating and unpleasant odor.

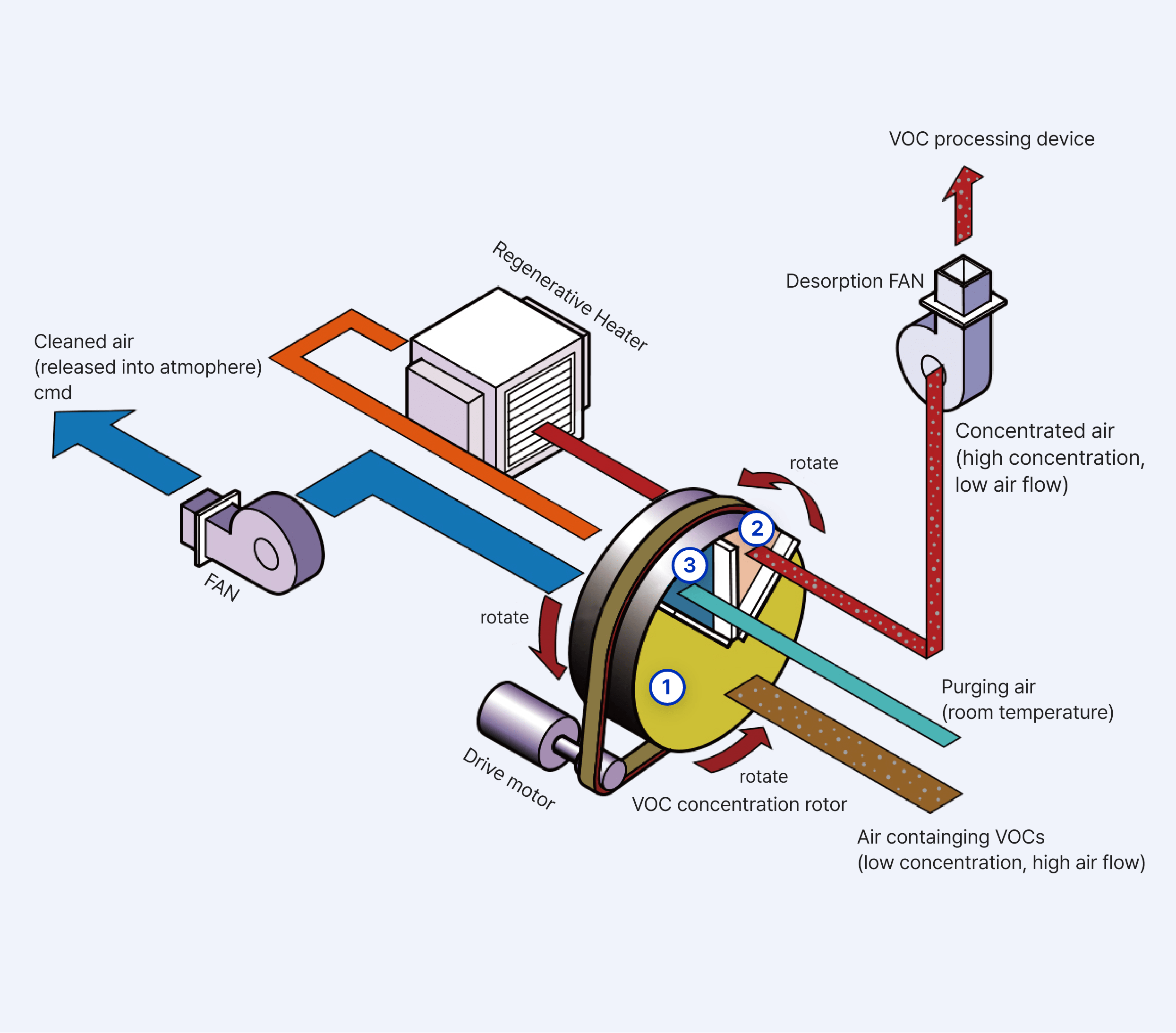

Therefore, VOCs must be controlled before releasing into the atmosphere. Before processing this, we use the "VOC Concentrated Honeycomb" rotor, which is a technology for collection. With using this technology, VOC-containing gas is concentrated from low to high concentration and from large air volume to small air volume.

We provide the EPC service for a system that oxidizes and decomposes by combustion with adsorption regeneration, cooling recovery, and heat storage combustion systems. And the filter device and a scrubber device are also provided to prevent the air pollution.

Principle of VOC Concentrator

Process Zone

VOC ADSORPTION

The VOC laden air is cleaned as VOC are adsorbed by the zeolite media as it passes through the rotor.

Regeneration Zone

VOC desorption and rotor regeneration

The rotor, which has adsorbed VOC, is rotated and moved into the regeneration zone, and the VOC are desorbed and concentrated by hot air flow (180 ~ 200°C). The concentration rate is about 3 ~ 30 times.

Cooling Zone

Rotor cooling and heat desorption

In order to recover the adsorption capacity of the media after it has been exposed to hot air inside the desorption zone; the media enters the cooling zone where it is cooled down by process air or fresh air. Simultaneously, the cooling air recovers heat energy as it passes through the rotor. This heated air is then used for desorption resulting in an energy efficient system.

Applications